Beam welding processes include laser beam welding (LBW) and electron beam welding (EBW). The welding beams can be focused to a very small spot size, which can be a small as the diameter of human hair — around 50 microns (0.05 mm). The beams are an extremely high energy density welding heat source with constant wave (CW) power densities as high as 105 kW/cm2. Most of the beam energy goes into melting the workpieces to form the weld. Only a limited portion of the beam energy is wasted in heating the surrounding metal, so the thickness of the heat-affected zone (HAZ) is minimized.

Depending on the beam focus, welding beams can perform in keyhole welding and conduction welding modes. Conduction beam welding occurs with larger beam spot sizes or lower power densities. Enough laser power is used to melt the metal without vaporization. Conduction welding produces shallower welds with smooth, attractive appearance. The conduction beam welding mode can be useful in surfacing and surface modification applications.

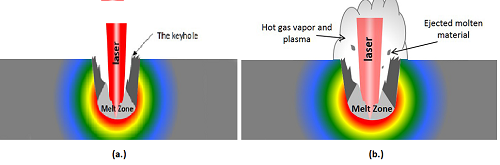

Keyhole welding occurs with a tightly focused, small spot size beam with a higher power density. The power density is high enough for the beam to vaporize the metal in a few milliseconds. The rapidly expanding vapor pushes melted metal to the side, which allows the beam to penetrate even deeper into the workpieces. A mixture of metal vapor, metal droplets and plasma (ionized vapor at temperatures near 10,000° C) forms, which partially ejects from the keyhole. Interactions of the laser beam with vapor-droplet-plasma mixture is a key factor in understanding, modeling and controlling the laser welding process.

Figure 1: “Keyhole” formation (a) and vapor-spray-plasma ejection (b) during high energy density laser welding. Source: Brian Simonds (NIST)

Figure 1: “Keyhole” formation (a) and vapor-spray-plasma ejection (b) during high energy density laser welding. Source: Brian Simonds (NIST)

Beam welding machines have significantly higher investment cost compared to conventional arc welding equipment. However, laser beam welding can be easily automated using computer-aided design (CAD) software. LBW can be more cost effective and profitable than arc welding for high volume welding where equipment is utilized around the clock. Laser and electron beam welding are non-contact processes, so there are no tools or electrodes to wear out. Another advantage of beam welding is the lack of filler metal consumption.

Beam welding requires accurate joint positioning and fit because the weld zone is extremely narrow and most applications are automated. High quality precision fixtures to assure alignment and seam tracking for repeatability results during beam welding. The ability to scan a beam across a surface remotely with scanning optics is an advantage of beam welding compared to arc welding, where the torch must be moved and work pieces repositioned in some cases. Beam welding processes can provide very precise targeting of joint seams. High precision fixtures enable full utilization of the precise scanning ability of beam welders.

Large high energy density laser or electron beam welders are not suitable for manual welding due to the burning and cutting danger of the beam. Safety should be a concern when using welding processes with intense high-power beams. Operators should be provided acceptable eye protection, x-ray radiation shielding, respirators to exclude vaporized metal fumes and protective clothing to prevent burns.

While beam welding is typically viewed as being less flexible compared to arc welding, smaller or benchtop manual laser welders and laser spot welders are available for mold repair and microwelding applications. In addition, a welding beam can be directed into cavities where even miniature TIG torches cannot fit.

联系人:Rob

微信:18666076565

手 机:18925189619 (In Mandarin, Cantonese & English)

电 话:020-31190575

邮 箱:sales@gzyuto.com

公 司:广州粤拓机电设备有限公司

地 址:广州市番禺区桥南街蚬涌村市南路653号102

网站: www.gzyuto.com